Aarsleff Felt Liner

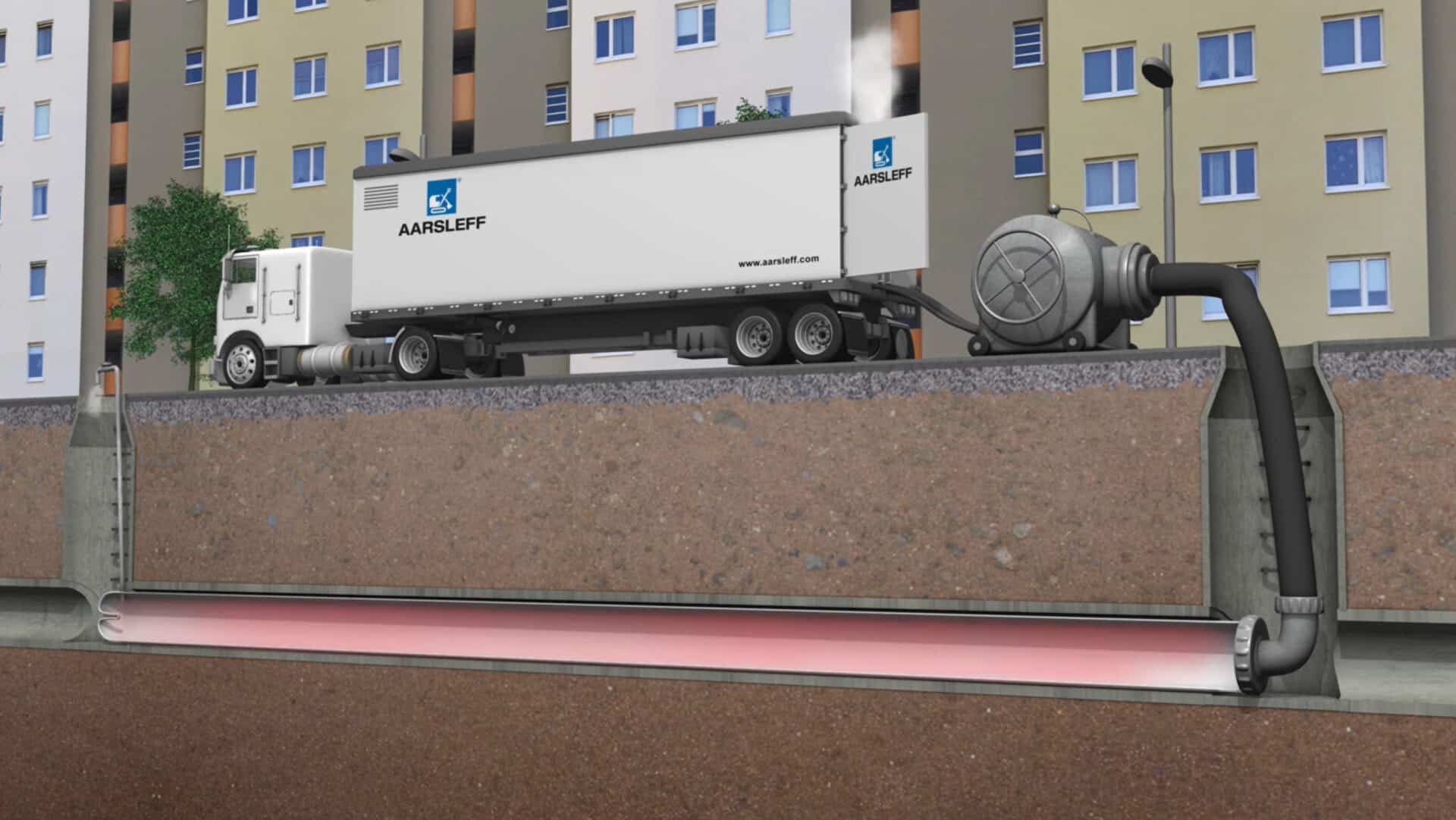

Steam installation

PAA-SF-Liner™

The PAA-SF-Liner™ consists of a multi-layered polyester needle felt with a high temperature resistant coating. Each felt liner is tailored to the individual installation at our ISO certified factory.

The felt laminate is built up by 1-7 layers; each sewn together by a longitudinal seam. To ensure that the laminate is homogeneous, the seam is displaced between the individual layers. The outer layer is coated with polypropylene (PP). The outer layer will become the new inside pipe wall after inversion.

Installation

A thin plastic preliner is installed to avoid water infiltration in the laminates during installation. The Aarsleff Felt liner is then rolled up inside an inversion drum. From the drum it is inverted inside the existing pipe by means of air pressure. When the liner is in place, the liner is cured by steam. Relining with steam as curing method makes it possible to make open end installations.

Installation time

The method is used for large dimensions. It is possible to carry out up to 3 installations per day. Often the installation time depends on the pipe length.

Approvals

Download print materials

Get to know more about Aarsleff felt liner installed with steam or discover more about our complete product portfolio.

Our projects

Aarsleff has decades of experience from projects across Europe. This experience is often drawn from our local subsidiaries, which means customers benefit from additional speed and efficiency.